Watching the kozo fibers floating in water is pure magic. Pouring bucket after bucket of the mix in paper frames is a luxury, knowing the process behind. In their own fields Awagami Factory are growing mulberry trees, and harvesting their own kozo during winter months. Only the inner bark is being used for paper, and the process from cutting the new growth to fibers is long, time consuming, and a row of people are involved, each presenting a unique skill.

Quote: “Since antiquity, Japanese washi has been made from renewable plant resources that reach maturity in 1-2 years. When compared to wood-based papers (that take dozens of years to mature and require many chemicals), washi is created with significantly less harm to our environment in a clean and eco-friendly manner. In the traditional spirit of Japan, Awagami papermaking maintains a caring and nurturing focus on the environment.”

Ayako-san has been such a great help for me during my visits to Awagami Factory. Here we are visiting Awagami´s kozo farm.

Ayako-san has been such a great help for me during my visits to Awagami Factory. Here we are visiting Awagami´s kozo farm.

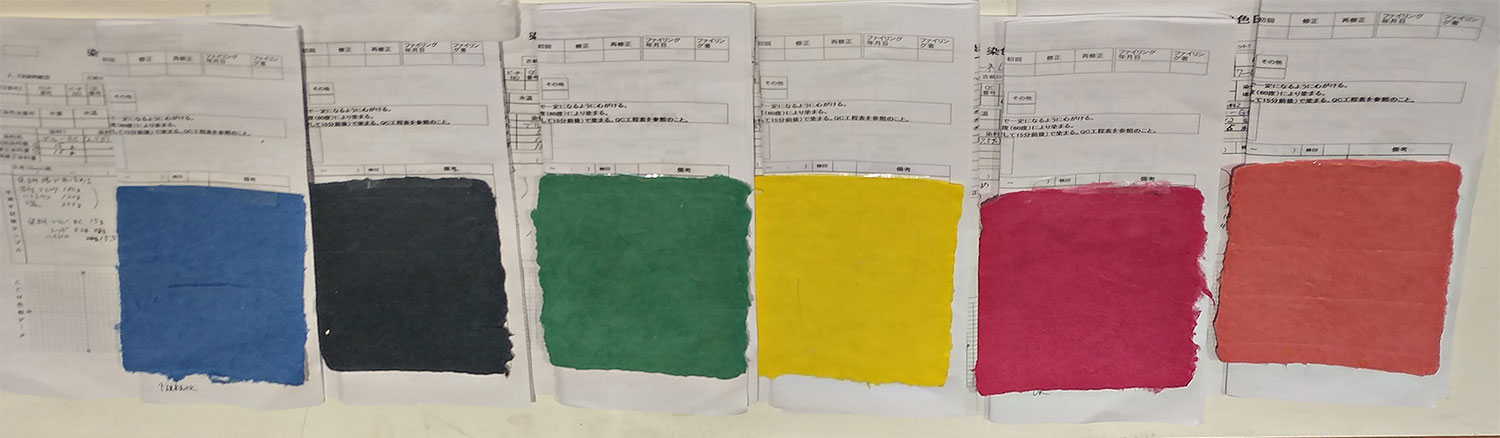

The process starts with my colour chart. I decide the colours I will need for my project, and how much of each, and when I arrive at the factory bags filled with pulp are waiting for me.

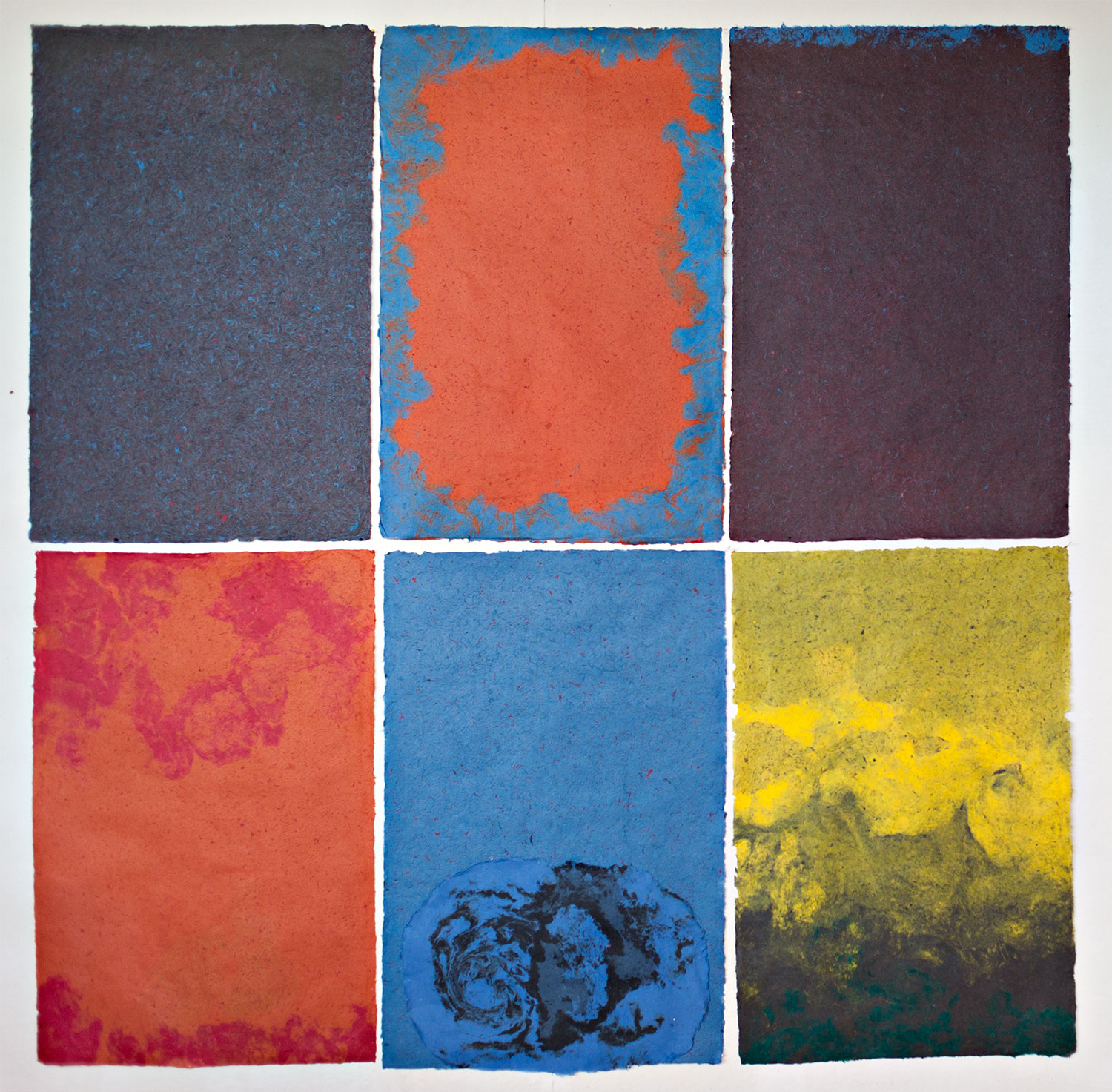

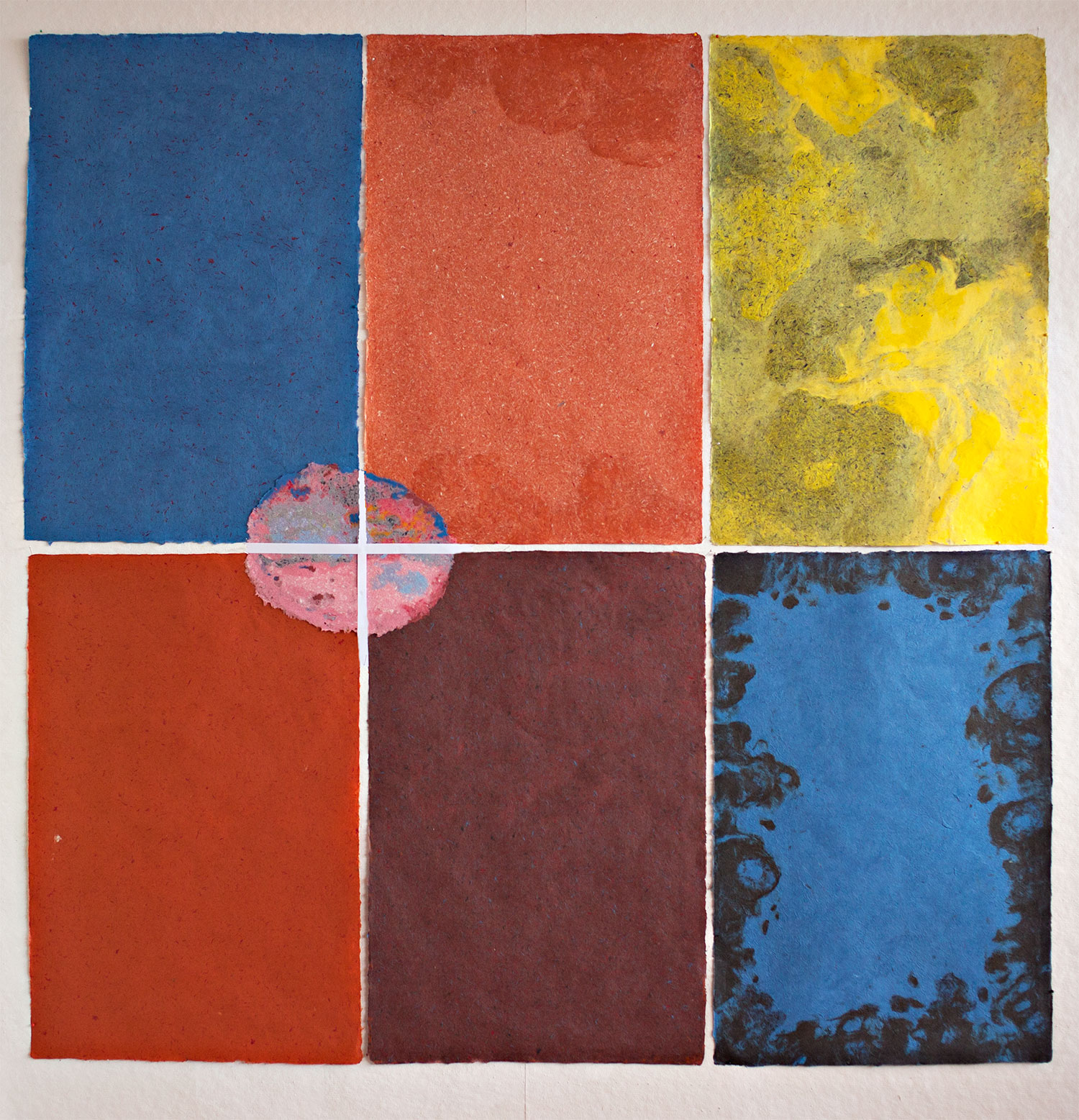

At the end of my stay as a visiting artist in 2019, I made these sheets (100 x 70 cm) from the remaining materials. It is possible to mix the colours to create a new, even colour, or like I did here, let the fibers float without mixing.

My intention was to print drypoints on these sheets. For the time being I have made assemblies of them, letting the colours do the job without interference, just adding a few collage pieces.

I love how the fibers are floating without mixing.